How to make your own cattle guard!

These videos give valuable insight in how to pour your own cattle guards from an actual job, with plenty of tips on how to easily make your own livestock barriers. See how easily you can have a gate-free facility. No more Gates to open and Close!

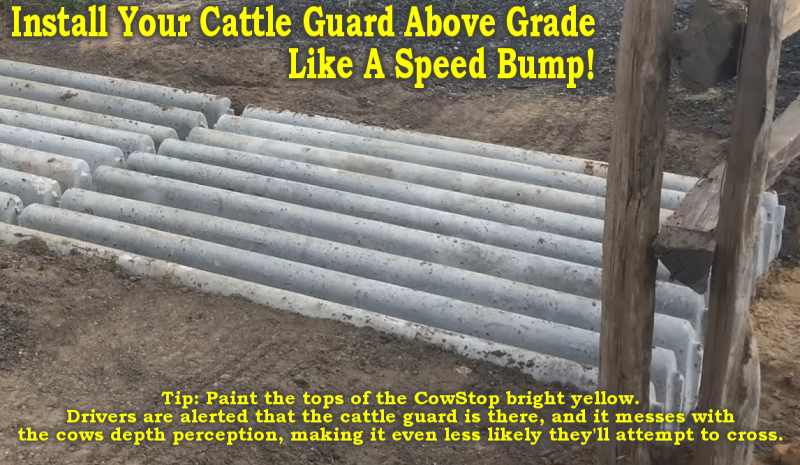

Important! Install cattle guards above grade!

The Cow Stop cattle guard when poured has its own base. There’s no pit to dig out. This does two things. First, it raises the Cow Stop up so debris and dirt wash out naturally. Second it make the cows even more reluctant to cross.

When combining multiple Cow Stops for large openings, grade the area so the forms make a speed bump to make the cows even more leary of crossing. Painting the tops of the forms bright yellow also confuses the cows, giving them one more reason not to test walking on them!

NOTE: All new Cow Stop forms are green in honor of the amount of money they save you compared to traditional metal cattle guards!

NOTE: All new Cow Stop forms are green in honor of the amount of money they save you compared to traditional metal cattle guards.

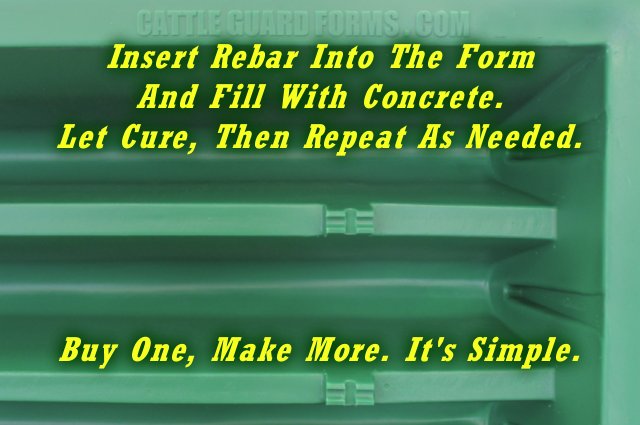

Buy One, Make More. It’s Simple

To make your own HS20-rated concrete Cow Stop cattle guard, place the form on a level surface and apply a concrete release agent inside the for. You can use silicon based release agents, or even plain vegetable oil. Place rebar in the slots, and pour 12 80 lb. bags of 4000 psi concrete into the form, and let it cure 3 or 4 days, remove form, reuse it again and again! Put each Cow Stop in place like building blocks or brick pavers in your opening and you’re done!

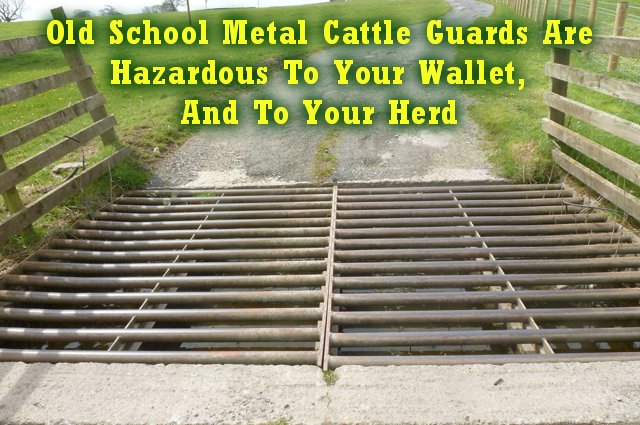

Maintenance free and nearly indestructible. They’re safer than open pit metal cattle guards. AND the materials to create a 7 ft. by 12 ft. cattle guard cost less than $600!